Comarch WMS

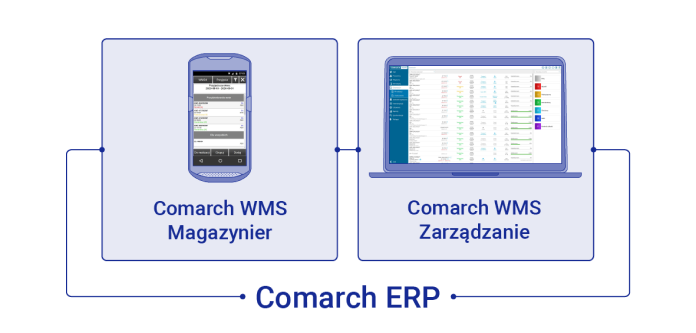

Comarch WMS is a package of two solutions – Comarch WMS Management and Comarch WMS Warehouseman, which together enable comprehensive high-storage warehouse management. Our WMS system allows for full control of the flow of goods in the company, thanks to full integration with Comarch ERP systems.

Comarch WMS includes, among others, a well-constructed warehouse structure, management algorithms, assignments assigned to employees, and monitoring of their status and time of completion. It also supports receiving and locating goods in the warehouse as well as issuing and inventorying them.

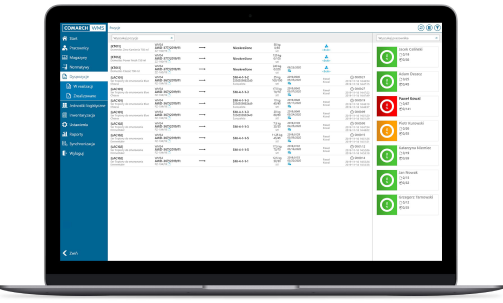

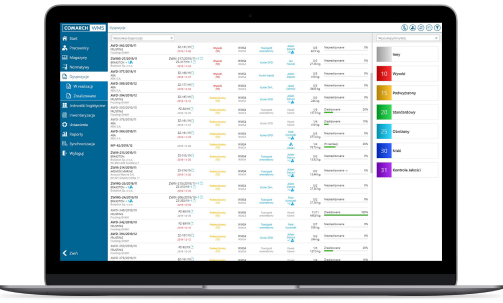

Comarch WMS Management contains the center of command of the warehouse and its processes. The web application is aimed at dispatchers and warehouse managers and allows, among other things:

- managing locations and controlling the relocation of resources in the warehouse

- monitoring the implementation of orders made by operators in the Comarch WMS Warehouseman application

- administering the permissions of warehousemen and adjusting the parameters of processes,

- controlling the minimum and maximum stock levels of goods,

- verifying the workload and ranking of warehousemen,

- configuring courier shipping orders,

- analyzing warehouse data using reports.

+48 514 087 878

+48 514 087 878  office@spaceit.tech

office@spaceit.tech  ul. Wschowska 8, 01-239 Warszawa

ul. Wschowska 8, 01-239 Warszawa